The Role of Underwater Maintenance in Extending Dry Dock Cycles for Cargo Ships

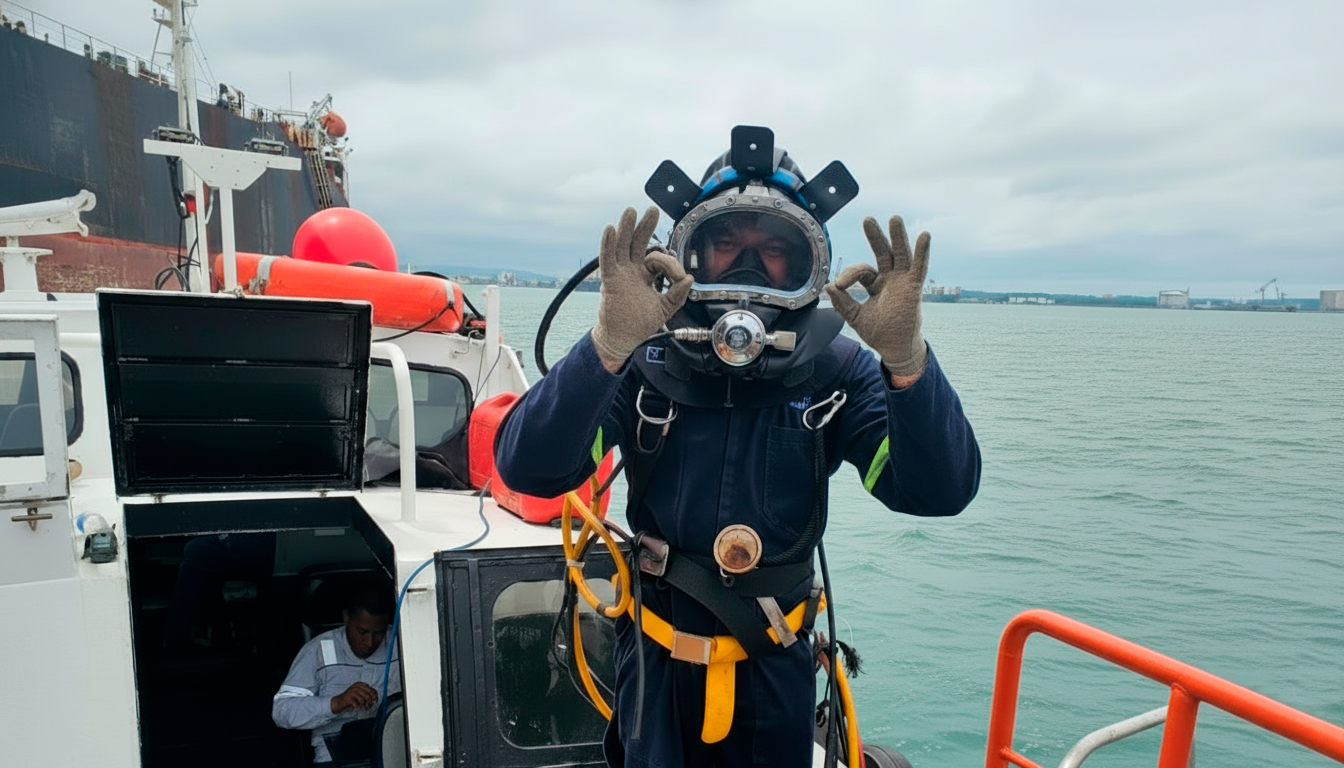

Dry docking a cargo vessel is a significant and unavoidable operational expense. For large shipping companies, reducing the frequency of these dockings without compromising safety or compliance can result in millions saved annually. One of the most effective ways to achieve this is through consistent, high-quality underwater maintenance. At Aquadiver Panamá, we specialize in helping commercial shipping clients extend the time between dry docks through proactive underwater cleaning, inspections, and repairs. In this article, we explore how underwater maintenance supports lifecycle extension, regulatory compliance, and operational efficiency for cargo vessels operating in and around Panama.

Why Dry Docking Is So Costly for Cargo Ships

Dry docking isn’t just about pulling a ship out of the water. It involves:

- Delays in cargo delivery schedules

- High fees for dockyard space and labor

- Regulatory inspections and class survey costs

- Painting, steelwork, and machinery overhauls

Each docking cycle represents a disruption to commercial service—and the average cost for a large container or bulk carrier can range between $500,000 to $1.5 million, depending on scope and region. For fleet operators working in tight economic conditions, especially post-pandemic, finding ways to extend dry dock intervals without risking detention or performance issues is a game changer.

Underwater Maintenance: The Preventive Alternative

Instead of waiting for the hull to deteriorate or fouling to build up to problematic levels, a proactive underwater maintenance program allows vessel owners to address issues in-water, often without interrupting cargo operations. At Aquadiver Panamá, our maintenance packages include:

- Scheduled hull cleaning (soft and hard brush)

- Propeller polishing

- Visual and video hull inspections

- Anode condition checks and replacement

- Sea chest and grid cleaning

- Minor in-water repairs (patching, blanking, removal)

Each of these services, when performed regularly, helps maintain hydrodynamic performance, protect coatings, and provide reliable data for class societies and technical superintendents.

1. Hull Cleaning and Biofouling Prevention

Marine growth begins forming within 7–10 days of anchoring in Panama’s warm, nutrient-rich waters. Left unchecked, this biofouling increases drag, decreases fuel efficiency, and accelerates paint wear. Regular underwater hull cleaning:

- Reduces fuel consumption by up to 10%

- Delays the need to recoat the hull

- Meets IMO performance standards

- Improves maneuverability and RPM consistency

By cleaning the hull every 3 to 6 months (depending on vessel activity), operators can postpone costly repainting and protect their coating system’s lifecycle.

2. Propeller Polishing to Preserve Shaft Efficiency

Propellers, like hulls, accumulate scale and barnacles. Even micro-level surface roughness causes vibration and reduces propulsion efficiency. Aquadiver’s underwater propeller polishing service includes:

- Grain-specific polishing pads (Class approved)

- Pre- and post-video for verification

- RPM monitoring during polishing

Polished propellers can improve fuel efficiency by 3–5% and reduce stress on propulsion systems, delaying shaft and bearing inspections typically done in dry dock.

3. Anode Monitoring and Replacement

Sacrificial anodes protect submerged steel components from corrosion. When neglected, this protection fails, accelerating metal fatigue. With in-water inspection and replacement, we:

- Assess wear on hull, rudder, and sea chest anodes

- Install replacement units using diver-secured brackets

- Document condition for class records

Maintaining anode health allows for safer intervals between dry docks and better alignment with class requirements.

4. Video Inspections for Decision-Makers

Every underwater maintenance operation is an opportunity to capture insights. Our divers record HD video footage during every cleaning or inspection, allowing clients to:

- Verify work quality

- Compare before/after cleaning impact

- Identify early warning signs of coating damage or corrosion

These reports are delivered in bilingual format (English/Spanish), with image tagging and timestamps—accepted by classification societies and flag authorities.

5. Emergency Repairs Between Dry Dockings

Sometimes small issues—such as a dislodged anode or minor rudder impact—don’t warrant full dry docking. In these cases, Aquadiver provides localized repair solutions underwater to buy more time and keep the vessel in service:

- Blanking leaking sea valves

- Removing ropes/nets entangled on shaft lines

- Installing temporary patches or epoxy solutions

We help clients stabilize the situation and plan for a more cost-effective intervention later.

How This Affects Dry Dock Scheduling

With structured underwater maintenance:

- Vessels can stretch dry dock cycles from 2.5 to 5 years

- Operators gain data to justify extensions to class

- Unexpected failures that force emergency dry dockings are avoided

Instead of reactive planning, shipping companies gain visibility and control—resulting in fewer surprises and better ROI.

Case Study: Bulk Carrier in the Gulf of Panama

A 210m bulk carrier operating on a South America–Asia route was due for dry dock in 18 months. But the operator was concerned about biofouling buildup and wanted to avoid premature coating failure. Aquadiver implemented a maintenance program that included quarterly hull cleanings, propeller polishing every 6 months, and visual anode checks. After 12 months of operations, the coating showed minimal wear and anodes were 70% intact. The vessel successfully deferred dry dock by an additional 9 months—saving an estimated $650,000 in rescheduling and loss of hire costs.

Why Aquadiver Is the Right Partner in Panama

We are not generalists—we only serve commercial vessels. Our divers understand port protocols, class standards, and shipping schedules. We operate across:

- Balboa

- Rodman

- Cristóbal

- MIT

- Colón 2000

And we offer 24/7 availability for scheduled or emergency underwater work.

Conclusion: Extend Dry Docking Cycles Without Risk

If you’re managing a cargo fleet transiting Panama or calling local ports, investing in underwater maintenance is not just preventive—it’s strategic. Aquadiver Panamá offers the tools, divers, and reporting you need to make informed decisions that protect your vessels and your budget. Contact us now to set up a tailored underwater maintenance program for your fleet.